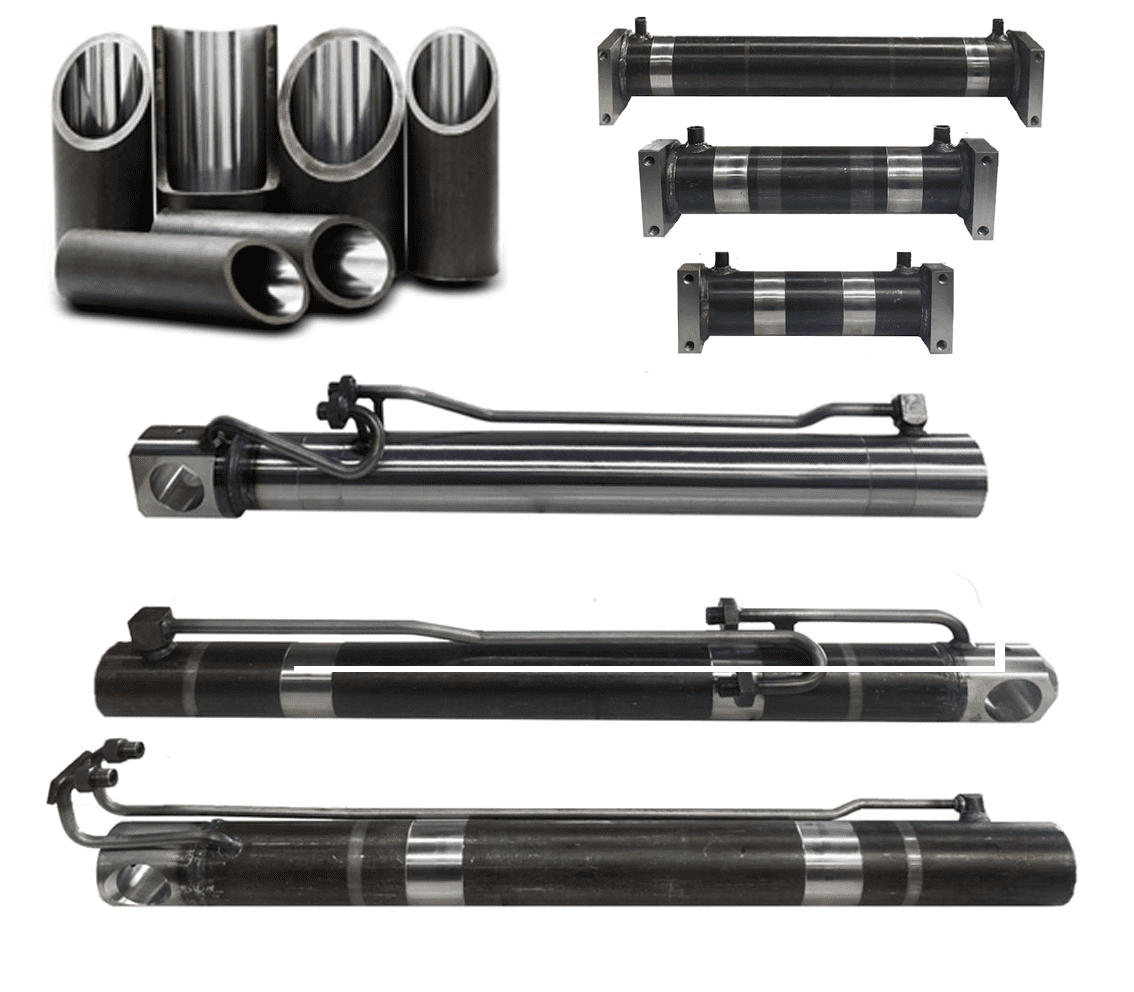

Cold Drawn Tubes | Seamless - CDS & Welded -CDW

At Kongu Enginears, we specialise in manufacturing and supplying a wide range of Cold Drawn Tubes, including both seamless and welded varieties. Our commitment to precision engineering, advanced technology, and quality assurance sets us apart as a reliable partner for industries seeking exceptional tube solutions.

Get a QuoteDescription

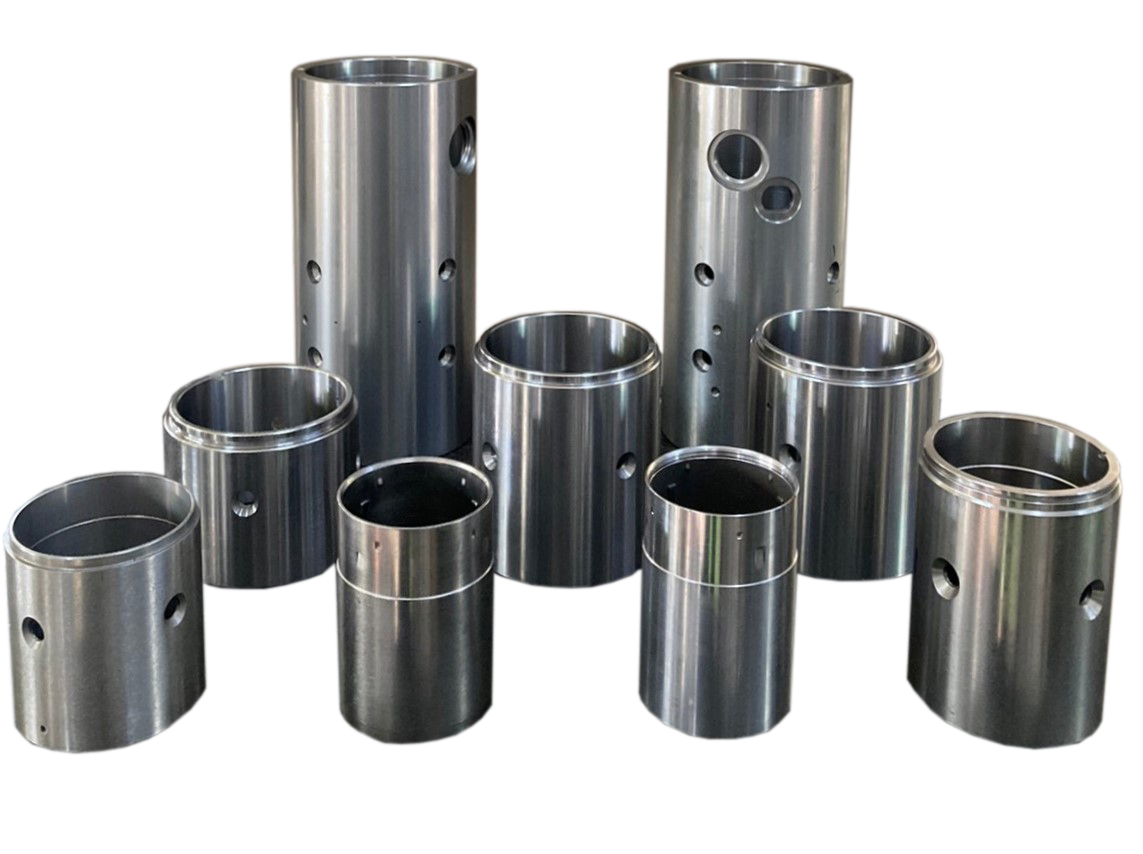

1. Seamless Cold Drawn TubesSeamless cold drawn tubes are produced without any welding or joining process, ensuring a homogeneous and continuous structure. The seamless design eliminates the risk of weak points or defects often associated with welded tubes, making them ideal for applications demanding high pressure, structural integrity, and smooth surfaces.

Advantages of Seamless Cold Drawn Tubes:

- Superior strength and integrity.

- Enhanced corrosion resistance.

- Smooth internal and external surfaces.

- Suitable for critical applications such as hydraulic systems, automotive components, and precision engineering.

Welded cold drawn tubes are created by joining two faces of material through welding and subsequently subjecting the assembly to cold drawing processes. This method allows for a diverse range of sizes and shapes, making welded tubes versatile for various applications.

Advantages of Welded Cold Drawn Tubes:

- Cost-effective production.

- High precision industrial application.

- Availability in a wide range of sizes and shapes.

- Suited for structural and decorative applications.

- Flexibility in material selection.

Why Choose Kongu Enginears' Cold Drawn Tubes?

Materials :

We offer cold drawn tubes in a variety of materials, including carbon steel, alloy steel, stainless steel, and non-ferrous alloys. This diverse material range ensures compatibility with the specific requirements of different industries.

Precision Manufacturing :

Our state-of-the-art facilities employ advanced cold drawing technology to ensure precision in dimensions, tight tolerances, and consistent quality. The result is tubes that meet or exceed industry standards.

Quality Assurance:

Rigorous quality control measures are implemented throughout the manufacturing process to guarantee the highest quality standards. Our commitment to quality extends to both seamless and welded cold drawn tubes.

Specification

- Carbon Steel, Alloy Steel & Stainless Steel