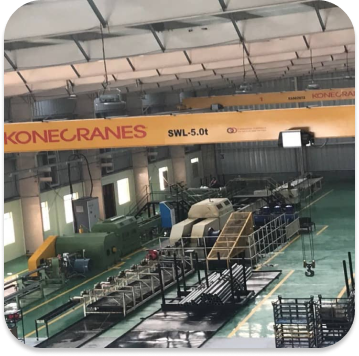

OUR MANUFACTURING FACILITY

Our four manufacturing facilities are located in close proximity to each other within the Industrial Zones of Coimbatore, Tamil Nadu, India, and collectively occupy an area of around 228,000 square feet.

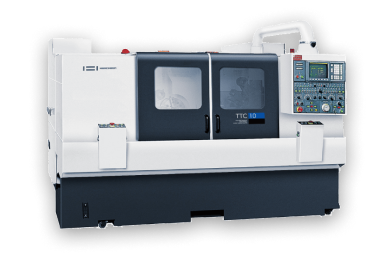

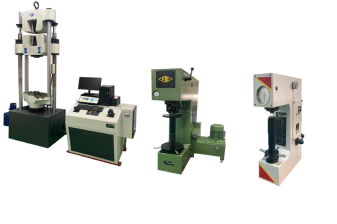

Well equipped with more than 85 World-class machines such as:

CNC Turning Centres & Turn Mill Centres

CNC Turning with Robotic loader

CNC Vertical Machining Centres Single & Twin Spindle

CNC Vertical Turning Lathe

Cold Tube Pilgering Machine

SIERRA (Made in USA) - Skiving and Roller Burnishing Machine (SRB)

Stainless Steel Tube mill

Automatic Tube Cutting Machines

Robotic welding Machines for MIG & TIG

Presses - Hydraulic, Pneumatic and Hydro Pneumatic